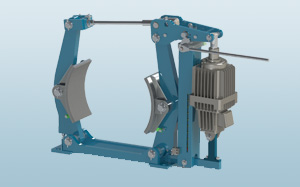

Drum Brakes

Drum brakes are for use whenever a constant brake torque is of utmost importance, not only for reasons of safety but also from a commercial standpoint. Mostly seen in applications like for instance Belt conveyer system, stacker and reclaim.

- Drum Brakes Options details

Drum Brakes

Function Principle

Spring applied, electrohydraulic thruster released

Brake torque adjustable

Brake applies in case of power failure ( Fail-Safe Principle)

Special features

Continuously adjustable brake spring enclosed in a square tube with torque scale

Spring protected by tube from damage and contamination

Automatic wear adjustment (AVN) guarantees even lifting gap

Equal air gap by bearing spring

Shoe clamping springs which prevent brake shoes from tilting when released

Self-lubricating bushings mean brakes are easy to service, no greasing necessary

Pins and nuts & bolts made of stainless steel

Options:

Automatic wear adjustment (AVN)

Monitoring devices: brake open/ brake close/ lifting gap monitoring

Special construction for horizontal and suspended mounting with support

Hand lifting device

Options details

AVN automatic wear adjustment

Automatic wear adjustment is used for compensation of lining wear. The wear adjustment takes place without paying attention to the remaining brake lining thickness.

However its compensating capacity per breaking cycle is limited. Therefore an additional manual wear compensation carried out by maintenance personnel is required according to the specific application.

If the brake is used as holding brake, then AVN is needless, for the abrasion hardly happens in this application.

Hand lifting device

The hand lever is used to open the brake manually in case of an emergency or to service the brake unit.

By pulling up the hand lever the mounted cam will force the knee lever up and thus open the brake. Secure the hand lever manually in position as long as the brake stays open.

Brake position control

One limit each can be used to monitor the following brake positions:

Closed

Opend

Adjust brake(check)- remaining stroke is marginal

The limit switches require no special maintenance. With rough conditions, following routine maintenance is recommended:

Check actuators of limit switch, shafts and rollers, for easy operation

Remove all dust, snow or ice etc.

Keep cams and roller shafts clean and lubricate slightly

Check sealing of cables or conduit connections

Damping valve

The damping valve is to slow down assembly of brake torque.